The Greasewatch patent is changing the game in industrial grease management, offering a cutting-edge solution to an age-old problem. With its advanced ultrasonic sensor technology, the Greasewatch patent is set to transform how businesses monitor and manage grease traps, making operations smoother and more efficient.

Unlike traditional methods that often fall short, the Greasewatch patent provides accurate, real-time monitoring of grease levels. This innovation helps prevent costly blockages and environmental issues, ensuring that grease traps are maintained effectively and in compliance with regulations.

The Greasewatch Patent: A New Era in Grease Management Technology

The Greasewatch patent marks a significant leap forward in grease management technology. It introduces advanced ultrasonic sensors that make monitoring grease levels more accurate than ever before. Traditional methods often struggle with grease buildup and environmental factors, but the Greasewatch patent addresses these issues head-on.

By using sound waves to detect grease levels, the Greasewatch patent offers real-time data that is reliable and precise. This innovation helps industries avoid costly disruptions caused by grease-related blockages, making operations smoother and more efficient.

- Businesses that adopt this technology will benefit from improved maintenance schedules and reduced downtime.

- The Greasewatch patent sets a new standard for how grease traps are monitored and managed, paving the way for more effective waste management solutions.

How the Greasewatch Patent is Transforming Industrial Waste Management

The Greasewatch patent is revolutionizing industrial waste management with its cutting-edge technology. Unlike older methods that can be inaccurate, this patent uses ultrasonic sensors to provide precise measurements of grease levels in real time.

This technology helps businesses avoid the common pitfalls of grease trap management, such as unexpected overflows and equipment malfunctions. By offering continuous monitoring, the Greasewatch patent ensures that grease traps are maintained properly, reducing the risk of costly repairs.

- Enhanced Monitoring: Real-time data ensures timely interventions and efficient grease management.

- Operational Efficiency: Improved systems lead to fewer maintenance issues and disruptions.

Why the Greasewatch Patent is a Game-Changer for Grease Trap Monitoring

The Greasewatch patent is changing the game in grease trap monitoring by providing a more accurate and reliable solution. Traditional grease monitoring methods can be hampered by grease buildup and environmental changes, but the Greasewatch patent overcomes these challenges with its ultrasonic technology.

- Ultrasonic Advantage: Sound waves provide precise readings without interference from grease buildup.

- Reduced Errors: Reliable data helps prevent blockages and maintenance issues, improving overall system performance.

Unveiling the Greasewatch Patent: The Future of Grease Management Systems

The Greasewatch patent represents the future of grease management systems with its innovative use of ultrasonic sensors. This patent introduces a modern approach to monitoring grease levels, making it a crucial tool for industries dealing with high volumes of fats, oils, and grease.

With its ability to provide real-time data and accurate measurements, the Greasewatch patent helps businesses stay ahead of potential issues.

- Future Potential: The technology is poised to become an essential component in industrial waste management.

- Benchmark Setting: The patent sets a new standard for grease management systems, shaping the future of the industry.

Greasewatch Patent vs. Traditional Methods: What Sets It Apart?

When comparing the Greasewatch patent to traditional grease monitoring methods, several key differences stand out. The Greasewatch patent utilizes ultrasonic sensors, which provide a higher level of accuracy compared to older capacitance-based systems.

- Accuracy: Ultrasonic sensors are less affected by grease buildup and environmental factors.

- Reliability: The technology offers more consistent monitoring, reducing the frequency of system failures.

Exploring the Cutting-Edge Features of the Greasewatch Patent

The Greasewatch patent introduces several cutting-edge features that set it apart from traditional grease management systems. One of the most notable features is its use of ultrasonic sensors to measure grease levels accurately.

- Ultrasonic Technology: Provides precise readings unaffected by grease buildup or environmental conditions.

- Self-Calibrating Feature: Adjusts automatically to maintain accuracy, reducing the need for manual adjustments.

How the Greasewatch Patent Enhances Accuracy and Reliability in Grease Monitoring

The Greasewatch patent significantly enhances accuracy and reliability in grease monitoring through its advanced ultrasonic sensor technology. Unlike traditional methods, which can be prone to inaccuracies due to grease buildup, the Greasewatch patent provides precise measurements by using sound waves.

- Consistent Data: Ensures accurate and reliable grease level monitoring.

- Improved Maintenance: Helps prevent blockages and operational issues, leading to better system performance.

The Role of the Greasewatch Patent in Preventing Environmental Hazards

The Greasewatch patent plays a crucial role in preventing environmental hazards by providing accurate grease level monitoring. By detecting grease buildup before it becomes a problem, this technology helps avoid spills and overflows that can damage the environment.

- Environmental Protection: Minimizes the risk of contamination of water systems.

- Regulatory Compliance: Helps businesses stay compliant with environmental regulations and reduce their impact.

Maximizing Efficiency with the Greasewatch Patent: A Comprehensive Guide

Maximizing efficiency with the Greasewatch patent involves leveraging its advanced features to improve grease management. This patent’s ultrasonic sensors provide accurate measurements of grease levels, allowing businesses to optimize their maintenance schedules.

- Streamlined Operations: Integration of the Greasewatch patent into existing systems improves efficiency.

- Reduced Downtime: Early detection of issues prevents costly repairs and disruptions.

The Self-Calibrating Advantage of the Greasewatch Patent

One of the standout features of the Greasewatch patent is its self-calibrating capability. This advantage allows the sensors to automatically adjust to changes in the grease trap environment, ensuring accurate readings at all times.

- Automatic Adjustments: Reduces the need for manual calibrations.

- Consistent Performance: Ensures reliable data even as conditions change.

Greasewatch Patent: The Ultimate Solution for Commercial Kitchen Waste Management

The Greasewatch patent offers the ultimate solution for waste management in commercial kitchens. Grease buildup is a common challenge in these environments, and the Greasewatch patent addresses it with advanced ultrasonic sensor technology.

- Real-Time Monitoring: Helps prevent blockages and maintenance issues in commercial kitchens.

- Regulatory Compliance: Ensures grease traps are managed efficiently, reducing the risk of environmental violations.

Don’t Miss This Recommendation: Unlock the Power of RXRR24 1.25: The Ultimate Guide to Enhancing Performance and Reliability

Understanding the Technology Behind the Greasewatch Patent

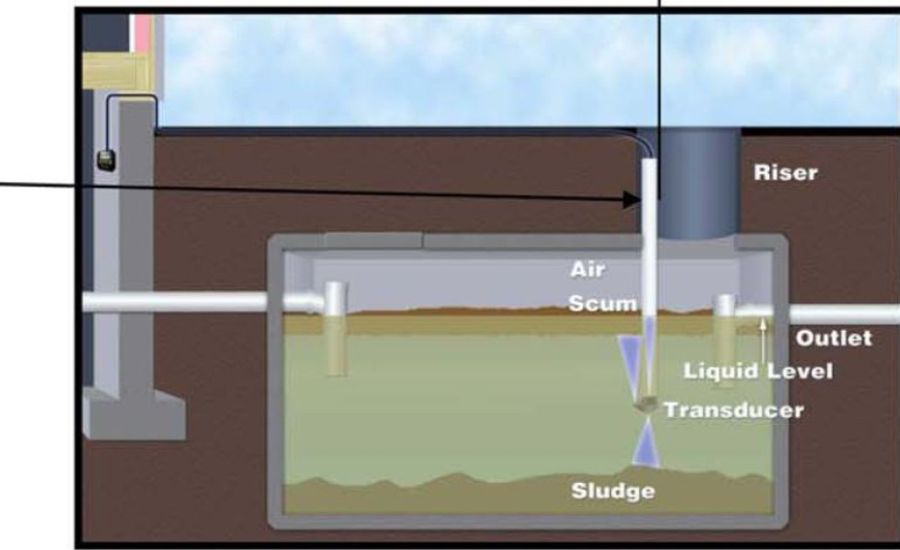

Understanding the technology behind the Greasewatch patent involves exploring its use of ultrasonic sensors. These sensors operate by emitting high-frequency sound waves that bounce off the grease surface and return to the sensor.

- Sound Wave Measurement: Provides accurate grease level readings by calculating the distance to the grease.

- Reliable Performance: Less affected by grease buildup and environmental conditions.

Greasewatch Patent and Regulatory Compliance: What You Need to Know

The Greasewatch patent plays a key role in helping businesses achieve regulatory compliance. Accurate grease monitoring is essential for meeting environmental regulations and avoiding potential fines or penalties.

- Regulatory Support: Provides reliable data to ensure compliance with environmental standards.

- Avoiding Penalties: Helps businesses manage grease traps effectively to avoid fines and legal issues.

The Economic Benefits of Adopting the Greasewatch Patent

Adopting the Greasewatch patent offers several economic benefits for businesses. The advanced ultrasonic sensors provide accurate grease level measurements, which help prevent costly blockages and maintenance issues.

- Cost Savings: Reduces expenses related to equipment repairs and downtime.

- Improved Efficiency: Lowers operational costs by minimizing the need for manual inspections.

How the Greasewatch Patent Stands Out in the Waste Management Industry

The Greasewatch patent stands out in the waste management industry due to its innovative use of ultrasonic sensors. Unlike traditional methods that can be less reliable, this technology offers precise and consistent measurements of grease levels.

- Unique Features: Ultrasonic sensors provide accurate data unaffected by external factors.

- Enhanced Performance: The patent’s technology sets a new benchmark in grease management.

Future Innovations: What’s Next for the Greasewatch Patent?

The future of the Greasewatch patent holds exciting possibilities for further innovations. As technology advances, we can expect enhancements in sensor capabilities and integration with other systems.

- Advanced Sensors: Future developments may include more sophisticated sensor technology.

- Expanded Features: Integration with remote monitoring and other systems could enhance functionality.

Case Studies: Success Stories with the Greasewatch Patent in Action

Case studies showcasing the Greasewatch patent highlight its success in various industries. These real-world examples demonstrate how the technology has improved grease management and operational efficiency.

- Successful Implementations: Businesses report fewer blockages and reduced maintenance costs.

- Proof of Effectiveness: Success stories provide evidence of the patent’s benefits and value.

Conclusion

The Greasewatch patent is changing how we manage grease in industries. With its smart ultrasonic sensors, it helps keep grease levels in check without the problems of old methods. This means fewer blockages, less maintenance, and a smoother operation for businesses. It’s like having a super helper that always knows when to fix things before they get messy.

Adopting the Greasewatch patent also means saving money and avoiding trouble with the law. By using this new technology, businesses can avoid costly repairs and stay in line with environmental rules. So, if you want to make grease management easier and more effective, the Greasewatch patent is a great choice to consider!

FAQs

Q: What is the Greasewatch patent?

A: The Greasewatch patent is a new technology that uses ultrasonic sensors to monitor grease levels in traps, offering more accurate and reliable readings than traditional methods.

Q: How does the Greasewatch system work?

A: It works by emitting high-frequency sound waves that bounce off the grease surface. The time it takes for the sound waves to return helps determine the grease level.

Q: What are the benefits of using Greasewatch?

A: Greasewatch provides precise measurements, reduces maintenance costs, prevents blockages, and helps businesses stay compliant with environmental regulations.

Q: Is the Greasewatch system easy to install?

A: Yes, it is designed for easy integration with existing grease traps and industrial systems, making it simple to set up and use.

Q: Can Greasewatch handle extreme temperatures?

A: Yes, Greasewatch’s ultrasonic sensors are built to withstand temperature changes, ensuring accurate readings even in varying conditions.

Q: How does Greasewatch compare to traditional methods?

A: Greasewatch offers greater accuracy and reliability than traditional capacitance-based probes, which can be affected by grease buildup and temperature changes.

Q: What kind of maintenance does the Greasewatch system require?

A: The system requires minimal maintenance due to its self-calibrating sensors, which automatically adjust for environmental changes and grease buildup.

Explore More: Unlock the Power of RXRR24 1.25: The Ultimate Guide to Enhancing Performance and Reliability

Наш интернет-магазин предлагает доставку свежие цветы прямо с голландских цветочных аукционов в любую точку Финляндии.

Мы выбираем только самые свежие и качественные цветы, чтобы подарить вам радость.

kimppuja Suomeen